Best Non-Rising Stem Gate Valve: Top Picks and Key Features for Reliability and Performance

2025-12-30

Welcome to our deep dive into the world of industrial valves, where reliability and performance are paramount. In this blog, we explore the best non-rising stem gate valves, key components in demanding applications that require durability, leak-tight sealing, and ease of operation. As you navigate through our top picks and essential features, you'll uncover insights to help optimize your systems and ensure long-term efficiency. To enhance your understanding, we're proud to integrate insights from DRIFCO, a leader in innovative valve solutions. Get ready to discover how these valves can elevate your projects—let's delve into the details that make a difference.

Exploring the Leading Non-Rising Stem Gate Valve Models

When delving into the world of industrial valves, non-rising stem gate valve models stand out for their unique design and practical applications. Unlike their rising stem counterparts, these valves feature a stem that rotates to open or close the gate without moving vertically, making them ideal for tight spaces or installations where vertical clearance is limited. Leading models often incorporate materials like stainless steel or bronze to handle high-pressure environments and corrosive fluids, ensuring durability and reliable performance in sectors such as water treatment, oil and gas, and chemical processing. Their compact build and efficient operation have made them a go-to choice for engineers seeking both functionality and space-saving solutions.

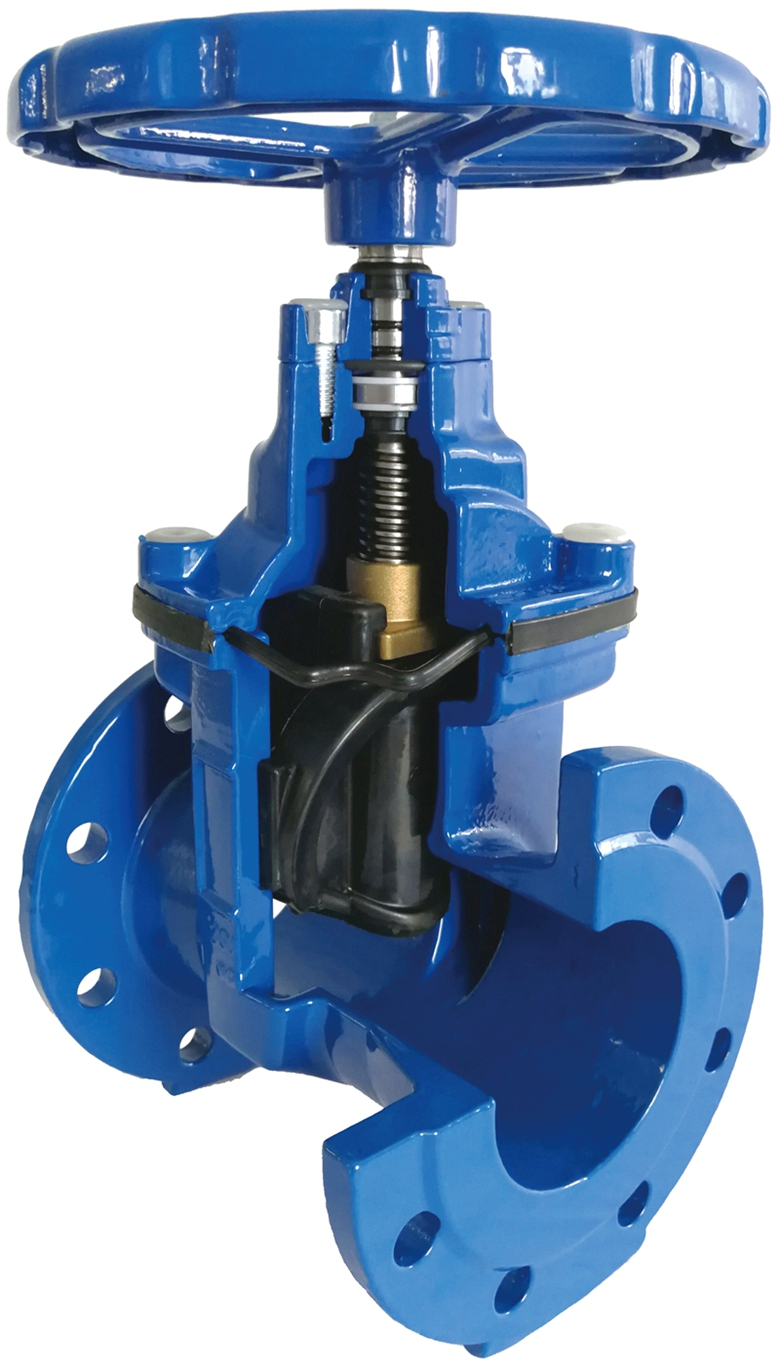

Among the top models, the OS&Y non-rising stem gate valve is particularly notable for its robust construction and ease of maintenance. It typically includes a yoke that shields the stem and packing, reducing wear and tear over time. Another standout is the flanged non-rising stem gate valve, which offers seamless integration into piping systems with its bolt-on design, enhancing leak resistance and stability under fluctuating pressures. These models often feature innovative sealing technologies, such as resilient seats or metal-to-metal seals, which prevent leakage and extend service life even in harsh conditions. By focusing on precision engineering and material quality, manufacturers ensure these valves meet stringent industry standards while minimizing downtime and operational costs.

To truly appreciate these leading models, it's helpful to compare them based on specific criteria like flow capacity, temperature tolerance, and maintenance requirements. For instance, some advanced versions incorporate automated actuators for remote control, adding versatility to manual designs. In applications ranging from fire protection systems to industrial cooling loops, non-rising stem gate valves prove their worth by offering consistent shut-off capabilities without sacrificing space or performance. As technology evolves, newer models continue to emerge with enhanced features like anti-corrosion coatings and improved stem designs, pushing the boundaries of efficiency and making them a smart investment for modern infrastructure projects.

Key Design Features Enhancing Durability and Flow Control

When it comes to boosting durability and refining flow control, certain design elements stand out for their ability to withstand tough conditions while keeping operations smooth. One major feature is the use of reinforced materials, like high-grade stainless steel or corrosion-resistant polymers, which can handle high pressures, extreme temperatures, and abrasive substances without wearing down quickly. This not only extends the lifespan but also minimizes maintenance needs, reducing downtime and unexpected repairs. Adding robust seals and gaskets from advanced elastomers ensures tight connections, preventing leaks and maintaining consistent performance even under fluctuating loads. By focusing on these material choices, the design sets a solid foundation for long-term reliability.

Another key aspect is the integration of innovative flow control mechanisms. Adjustable throttling valves, for instance, allow precise modulation of fluid or gas rates, enabling users to fine-tune processes for optimal efficiency. This adaptability is crucial in environments where demands vary, such as in manufacturing lines or chemical plants. Moreover, smart features like self-cleaning filters or automated shut-off systems help maintain flow integrity by preventing clogs and overflows, which can otherwise lead to damage or inefficiencies. These designs prioritize intuitive operation, often with user-friendly interfaces that simplify control without requiring extensive technical expertise, making them accessible while enhancing overall system resilience.

To really stand out, durability isn't just about brute strength—it's about smart engineering that anticipates real-world challenges. For example, modular components can be easily replaced or upgraded without overhauling the entire system, saving time and resources. Heat dissipation designs, such as fins or cooling channels, prevent overheating that might degrade materials or disrupt flow dynamics. By blending these practical solutions with aesthetic touches like sleek, ergonomic shapes, the design not only performs reliably but also fits seamlessly into modern setups. This holistic approach ensures that both durability and flow control are enhanced in a way that feels tailored and forward-thinking, rather than just following standard templates.

Material Selection for Optimal Corrosion Resistance and Longevity

Choosing the right materials is crucial for ensuring that structures and components withstand corrosive environments and last for decades. It's not just about picking stainless steel or aluminum; it involves a deep dive into factors like chemical exposure, temperature fluctuations, and mechanical stresses. By carefully assessing these conditions, engineers can tailor material choices to delay degradation, reduce maintenance costs, and extend service life significantly.

In practice, this means going beyond standard catalog recommendations. For instance, in marine applications, duplex stainless steels might outperform 316 stainless due to their superior resistance to pitting and crevice corrosion. Similarly, coatings and surface treatments, such as anodizing or galvanizing, can enhance base materials by adding protective layers that shield against aggressive elements. This proactive approach turns material selection into a strategic investment rather than a routine specification.

Ultimately, the goal is to balance performance with practicality. Materials like titanium offer exceptional corrosion resistance but come with higher costs, whereas carbon steel with proper coatings might suffice in less harsh settings. By integrating lifecycle analysis and real-world testing, teams can make informed decisions that not only prevent premature failures but also contribute to sustainability by minimizing replacements and waste. This thoughtful process ensures longevity without overengineering, keeping projects both robust and economical.

Performance Benchmarks in High-Pressure Industrial Applications

In high-pressure industrial environments, performance benchmarks serve as crucial metrics to gauge the reliability and efficiency of equipment under extreme conditions. These benchmarks often include stress testing for components like valves, pumps, and compressors, ensuring they withstand pressures exceeding standard operating levels without failure.

By establishing clear performance criteria, industries such as oil and gas or chemical processing can minimize downtime and safety risks. For instance, benchmarks might measure leak rates, material deformation, or thermal stability, providing actionable data to optimize maintenance schedules and enhance operational resilience.

Beyond mere compliance, forward-thinking companies leverage these benchmarks to drive innovation, comparing results across different technologies to select the most robust solutions. This approach not only boosts productivity but also fosters a culture of continuous improvement in high-stakes settings.

Maintenance Tips to Ensure Smooth Operation Over Time

Keeping your equipment running smoothly over the long haul isn't just about fixing problems when they pop up; it's about being proactive with regular check-ups and adjustments. Think of it like taking your car for a tune-up before it starts making strange noises—it can save you from costly breakdowns and extend the lifespan of your gear. By scheduling routine inspections and cleaning out dust or debris, you'll catch minor issues early, ensuring everything operates at peak performance without unexpected hiccups.

Another key aspect is staying on top of software updates and firmware upgrades, which often include patches for bugs and improvements that enhance stability. Don't let outdated systems drag you down; a simple update can prevent compatibility issues and security vulnerabilities. Plus, keeping a log of maintenance activities helps you track patterns and anticipate needs, making it easier to plan ahead rather than react to emergencies.

Lastly, consider the environment where your equipment is used—factors like temperature, humidity, and power fluctuations can quietly wear things down. Installing surge protectors or ensuring proper ventilation might seem like small steps, but they add up to big benefits in preventing wear and tear. By integrating these habits into your routine, you'll foster a smoother, more reliable operation that stands the test of time without constant intervention.

Comparative Analysis with Rising Stem Valves for Informed Decisions

When selecting valves for industrial applications, a comparative analysis with rising stem valves is crucial for making informed decisions that balance performance and cost. Unlike other valve types, rising stem valves feature a stem that moves up and down as the valve opens or closes, providing clear visual indications of position. This makes them particularly useful in systems where operator awareness is paramount, such as in high-pressure pipelines or safety-critical operations.

In practice, comparing rising stem valves to alternatives like quarter-turn or non-rising stem valves reveals distinct advantages in maintenance and longevity. For instance, the linear motion of the stem reduces wear on internal components, leading to fewer leaks and longer service intervals. This can translate to significant savings over time, especially in applications with frequent cycling or harsh environmental conditions. By evaluating factors such as ease of repair and resistance to corrosion, decision-makers can tailor their choices to specific operational needs, ensuring durability without unnecessary expenditure.

Ultimately, this analysis empowers professionals to go beyond basic specifications and consider real-world implications. Whether for upgrading existing infrastructure or designing new systems, understanding how rising stem valves interact with fluid dynamics and control mechanisms leads to smarter, more efficient installations. By prioritizing clarity in valve status and reliability in performance, organizations can mitigate risks and enhance overall system integrity, making every decision a step toward optimized operations.

FAQ

Non-rising stem gate valves are praised for reliability because they're compact and ideal for tight spaces, with the stem staying in place during operation to reduce external exposure—minimizing wear and corrosion. This design often features durable materials like stainless steel or brass, ensuring long-term performance in harsh conditions without needing frequent adjustments.

Leading models excel in high-pressure settings by incorporating robust construction, such as reinforced bodies and precision-machined gates, which prevent leaks and maintain sealing integrity. Many also include pressure-rated designs, like those tested to ANSI standards, ensuring safe operation even under extreme stress without compromising flow control.

For peak performance, focus on features like full-port designs that minimize flow restriction, anti-corrosion coatings to resist chemical damage, and easy-operating mechanisms such as handwheels or actuators. Additionally, check for tight shut-off capabilities and compatibility with various media, from water to aggressive fluids, to match your specific usage needs.

This type is often favored in confined areas or where overhead clearance is limited, as the stem doesn't extend outward during use—keeping the overall height lower. It's also less prone to dirt accumulation and external damage, making it a practical choice for underground or crowded piping systems where maintenance access is tricky.

Top-tier valves stand out with enhanced durability through features like forged or cast bodies for extra strength, high-grade stem materials that resist galling, and leak-proof packing seals. Many undergo rigorous testing, such as cycle life assessments, to ensure they withstand repeated use without failure, offering a longer service life than standard options.

Contemporary models often include ergonomic improvements, such as color-coded handles for quick identification, smooth-gliding stems to reduce operating torque, and clear position indicators. Some even come with pre-lubricated components or modular designs for straightforward installation and maintenance, cutting down on downtime in industrial settings.

Sealing mechanisms are critical for reliability, as they prevent leaks and ensure tight shut-off. The best valves use advanced seals, like PTFE or graphite packing, that adapt to temperature and pressure changes. This maintains a secure barrier against media escape, reducing the risk of contamination or system inefficiencies over time.

Conclusion

In exploring top non-rising stem gate valve models, several standout options demonstrate exceptional reliability and performance. These valves are engineered with key design features that enhance durability and precise flow control, such as compact designs that save space while maintaining robust sealing mechanisms. Material selection plays a critical role, with alloys like stainless steel and bronze offering optimal corrosion resistance and longevity, ensuring these valves withstand harsh environments. Performance benchmarks in high-pressure industrial applications reveal that leading models maintain integrity under extreme conditions, minimizing leakage and operational downtime. By integrating these aspects, the best non-rising stem gate valves prove to be indispensable for demanding settings, combining efficiency with long-term resilience.

Effective maintenance tips further ensure smooth operation over time, including regular inspection of seals and lubrication of internal components. A comparative analysis with rising stem valves highlights advantages like reduced installation height and lower maintenance needs, aiding informed decisions for specific applications. This comprehensive approach—melding design innovation, material science, and practical upkeep—positions top picks as superior choices for reliability and performance. Ultimately, these valves offer a balanced solution that excels in both static and dynamic systems, distinguishing themselves through tailored features that prioritize user convenience and operational excellence in various industrial contexts.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com