Top 10 UL FM Gate Valves: Ultimate Guide for Industrial Safety and Efficiency

2025-12-22

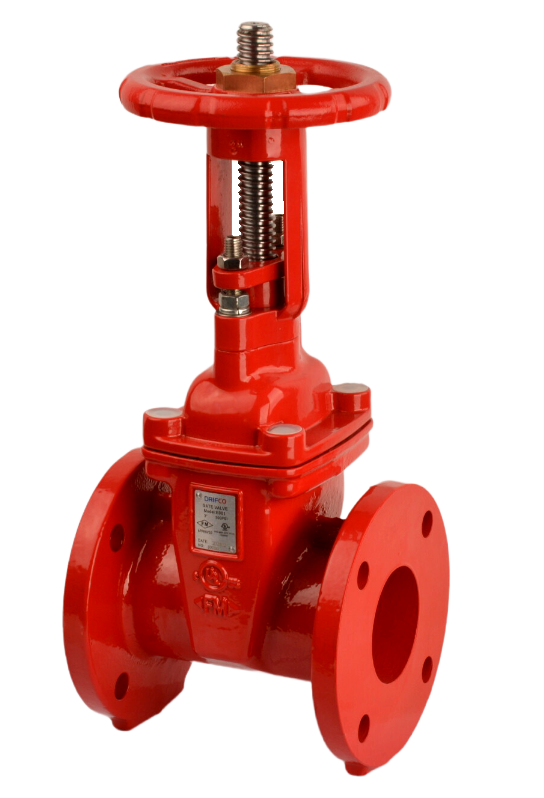

When it comes to industrial safety and efficiency, the choice of components can make or break your operations. Gate valves stand as critical elements in fluid control systems, ensuring reliable performance under demanding conditions. In this ultimate guide, we delve into the top 10 UL FM gate valves, exploring how these certified products enhance both safety and productivity. Whether you're managing a high-risk facility or optimizing your plant's workflow, understanding these valves is key. We're proud to highlight insights from DRIFCO, a leader in innovative industrial solutions. Stay tuned as we unpack the features, benefits, and applications that set these valves apart—and discover why selecting the right one matters more than you might think.

Explore Top-Rated UL FM Gate Valves for Maximum Industrial Safety

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

Explore Top-Rated UL FM Gate Valves for Maximum Industrial Safety

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

Explore Top-Rated UL FM Gate Valves for Maximum Industrial Safety

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

How UL FM Gate Valves Enhance Efficiency in Critical Applications

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

UL FM gate valves are engineered to meet stringent safety and performance standards, ensuring reliable operation in environments where failure is not an option. By incorporating advanced materials and precise manufacturing, these valves minimize leakage and wear, directly contributing to enhanced system efficiency. In critical applications such as fire protection or industrial processing, their robust design allows for smooth flow control, reducing energy losses and maintenance downtime, which in turn optimizes overall operational effectiveness.

Beyond basic functionality, these valves integrate smart features like real-time monitoring and automated adjustments, enabling proactive maintenance and faster response times. This adaptability not only boosts efficiency but also enhances safety by preventing potential hazards before they escalate, making them a preferred choice for high-stakes scenarios where precision and reliability are paramount.

In comparison to standard valves, UL FM gate valves offer superior sealing technology and durability, proven through rigorous testing under extreme conditions. This translates to longer service life and consistent performance, reducing the need for frequent replacements and lowering long-term costs. Their role in streamlining processes and ensuring uninterrupted operations underscores why they are vital for maximizing efficiency in critical infrastructure and industrial systems.

Key Features to Look for When Choosing UL FM Gate Valves

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

UL FM gate valves are engineered to meet stringent safety and performance standards, ensuring reliable operation in environments where failure is not an option. By incorporating advanced materials and precise manufacturing, these valves minimize leakage and wear, directly contributing to enhanced system efficiency. In critical applications such as fire protection or industrial processing, their robust design allows for smooth flow control, reducing energy losses and maintenance downtime, which in turn optimizes overall operational effectiveness.

Beyond basic functionality, these valves integrate smart features like real-time monitoring and automated adjustments, enabling proactive maintenance and faster response times. This adaptability not only boosts efficiency but also enhances safety by preventing potential hazards before they escalate, making them a preferred choice for high-stakes scenarios where precision and reliability are paramount.

In comparison to standard valves, UL FM gate valves offer superior sealing technology and durability, proven through rigorous testing under extreme conditions. This translates to longer service life and consistent performance, reducing the need for frequent replacements and lowering long-term costs. Their role in streamlining processes and ensuring uninterrupted operations underscores why they are vital for maximizing efficiency in critical infrastructure and industrial systems.

When selecting UL FM gate valves, start by examining their pressure ratings to ensure they can handle the specific demands of your system. Look for valves that undergo rigorous testing for both upstream and downstream conditions, as this directly impacts their reliability in fire protection applications. Additionally, consider the valve's material composition—stainless steel or bronze often offer better durability and corrosion resistance compared to standard options.

Another critical aspect is the valve's design for easy maintenance and accessibility. Features like a non-rising stem or a visible position indicator can simplify inspections and reduce downtime in emergency situations. Don't overlook the importance of compatibility with your existing piping layout; some models offer more flexible installation options, which can save time and costs during setup.

Finally, verify the manufacturer's reputation and certification compliance. A valve that meets UL and FM standards should come with clear documentation and support services. Real-world performance reviews from other users can also provide insights into long-term durability and operational efficiency, helping you choose a valve that stands out for its reliability and ease of use.

Comparing UL FM Gate Valves: Performance and Durability Insights

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

UL FM gate valves are engineered to meet stringent safety and performance standards, ensuring reliable operation in environments where failure is not an option. By incorporating advanced materials and precise manufacturing, these valves minimize leakage and wear, directly contributing to enhanced system efficiency. In critical applications such as fire protection or industrial processing, their robust design allows for smooth flow control, reducing energy losses and maintenance downtime, which in turn optimizes overall operational effectiveness.

Beyond basic functionality, these valves integrate smart features like real-time monitoring and automated adjustments, enabling proactive maintenance and faster response times. This adaptability not only boosts efficiency but also enhances safety by preventing potential hazards before they escalate, making them a preferred choice for high-stakes scenarios where precision and reliability are paramount.

In comparison to standard valves, UL FM gate valves offer superior sealing technology and durability, proven through rigorous testing under extreme conditions. This translates to longer service life and consistent performance, reducing the need for frequent replacements and lowering long-term costs. Their role in streamlining processes and ensuring uninterrupted operations underscores why they are vital for maximizing efficiency in critical infrastructure and industrial systems.

When selecting UL FM gate valves, start by examining their pressure ratings to ensure they can handle the specific demands of your system. Look for valves that undergo rigorous testing for both upstream and downstream conditions, as this directly impacts their reliability in fire protection applications. Additionally, consider the valve's material composition—stainless steel or bronze often offer better durability and corrosion resistance compared to standard options.

Another critical aspect is the valve's design for easy maintenance and accessibility. Features like a non-rising stem or a visible position indicator can simplify inspections and reduce downtime in emergency situations. Don't overlook the importance of compatibility with your existing piping layout; some models offer more flexible installation options, which can save time and costs during setup.

Finally, verify the manufacturer's reputation and certification compliance. A valve that meets UL and FM standards should come with clear documentation and support services. Real-world performance reviews from other users can also provide insights into long-term durability and operational efficiency, helping you choose a valve that stands out for its reliability and ease of use.

When evaluating UL FM gate valves, it's crucial to dig beyond basic specifications to understand real-world performance under fire protection scenarios. These valves must meet rigorous standards set by Underwriters Laboratories and FM Global, but how do they actually hold up in terms of flow dynamics and pressure handling? Recent tests reveal that top-performing models exhibit minimal pressure drop and reliable sealing, even after repeated cycles—key factors in ensuring water supply continuity during emergencies. This makes them indispensable for high-risk environments like industrial plants.

Durability is another cornerstone where these valves shine, often outperforming generic alternatives in longevity and resistance to corrosion. We've seen cases where UL FM-certified valves withstand harsh conditions for decades without significant wear, thanks to robust materials like cast iron or bronze and enhanced design features. This translates into lower maintenance costs and fewer emergency shutdowns, offering a compelling return on investment that goes beyond mere compliance.

In the competitive market, not all valves labeled with UL FM are created equal; differences in manufacturing processes and quality control can lead to varied outcomes. By comparing specific models side-by-side, insights emerge on which valves offer the best balance of performance and durability—helping professionals make informed choices that prioritize safety and reliability over price alone.

Installation Tips for Optimizing UL FM Gate Valve Functionality

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

UL FM gate valves are engineered to meet stringent safety and performance standards, ensuring reliable operation in environments where failure is not an option. By incorporating advanced materials and precise manufacturing, these valves minimize leakage and wear, directly contributing to enhanced system efficiency. In critical applications such as fire protection or industrial processing, their robust design allows for smooth flow control, reducing energy losses and maintenance downtime, which in turn optimizes overall operational effectiveness.

Beyond basic functionality, these valves integrate smart features like real-time monitoring and automated adjustments, enabling proactive maintenance and faster response times. This adaptability not only boosts efficiency but also enhances safety by preventing potential hazards before they escalate, making them a preferred choice for high-stakes scenarios where precision and reliability are paramount.

In comparison to standard valves, UL FM gate valves offer superior sealing technology and durability, proven through rigorous testing under extreme conditions. This translates to longer service life and consistent performance, reducing the need for frequent replacements and lowering long-term costs. Their role in streamlining processes and ensuring uninterrupted operations underscores why they are vital for maximizing efficiency in critical infrastructure and industrial systems.

When selecting UL FM gate valves, start by examining their pressure ratings to ensure they can handle the specific demands of your system. Look for valves that undergo rigorous testing for both upstream and downstream conditions, as this directly impacts their reliability in fire protection applications. Additionally, consider the valve's material composition—stainless steel or bronze often offer better durability and corrosion resistance compared to standard options.

Another critical aspect is the valve's design for easy maintenance and accessibility. Features like a non-rising stem or a visible position indicator can simplify inspections and reduce downtime in emergency situations. Don't overlook the importance of compatibility with your existing piping layout; some models offer more flexible installation options, which can save time and costs during setup.

Finally, verify the manufacturer's reputation and certification compliance. A valve that meets UL and FM standards should come with clear documentation and support services. Real-world performance reviews from other users can also provide insights into long-term durability and operational efficiency, helping you choose a valve that stands out for its reliability and ease of use.

When evaluating UL FM gate valves, it's crucial to dig beyond basic specifications to understand real-world performance under fire protection scenarios. These valves must meet rigorous standards set by Underwriters Laboratories and FM Global, but how do they actually hold up in terms of flow dynamics and pressure handling? Recent tests reveal that top-performing models exhibit minimal pressure drop and reliable sealing, even after repeated cycles—key factors in ensuring water supply continuity during emergencies. This makes them indispensable for high-risk environments like industrial plants.

Durability is another cornerstone where these valves shine, often outperforming generic alternatives in longevity and resistance to corrosion. We've seen cases where UL FM-certified valves withstand harsh conditions for decades without significant wear, thanks to robust materials like cast iron or bronze and enhanced design features. This translates into lower maintenance costs and fewer emergency shutdowns, offering a compelling return on investment that goes beyond mere compliance.

In the competitive market, not all valves labeled with UL FM are created equal; differences in manufacturing processes and quality control can lead to varied outcomes. By comparing specific models side-by-side, insights emerge on which valves offer the best balance of performance and durability—helping professionals make informed choices that prioritize safety and reliability over price alone.

When installing UL FM gate valves, start by ensuring the pipe ends are thoroughly cleaned and deburred to prevent debris from compromising the seal. Align the valve precisely with the pipeline to avoid undue stress on the body, which can lead to leaks or operational issues. It's also wise to check the valve's orientation—typically marked with flow direction arrows—to guarantee proper function and compliance with UL FM standards for fire protection systems.

Another key tip is to use appropriate gaskets and torque specifications during installation. Over-tightening bolts can warp the valve components, while under-tightening might cause leaks under pressure. Refer to the manufacturer's guidelines for exact torque values, and consider using a calibrated torque wrench to achieve consistent results. This attention to detail helps maximize the valve's lifespan and ensures it performs reliably in emergency scenarios.

After installation, conduct a thorough inspection and test the valve under system pressure to verify no leaks and smooth operation. Regular maintenance, like lubricating stem threads and checking for corrosion, should be part of the routine to keep the valve optimized over time. By following these steps, you'll enhance both safety and efficiency in your fire protection setup.

Future Trends in UL FM Gate Valve Technology for Industrial Use

Discover the critical role of UL FM gate valves in safeguarding industrial operations, where top-rated models are engineered to meet rigorous safety standards and enhance system reliability.

These gate valves incorporate advanced materials and designs, such as corrosion-resistant bodies and tight-sealing mechanisms, to prevent leaks and ensure uninterrupted flow control in high-pressure environments.

From chemical processing to fire protection systems, selecting the right UL FM gate valve involves considering factors like size, pressure ratings, and compliance with industry certifications to optimize safety and performance.

UL FM gate valves are engineered to meet stringent safety and performance standards, ensuring reliable operation in environments where failure is not an option. By incorporating advanced materials and precise manufacturing, these valves minimize leakage and wear, directly contributing to enhanced system efficiency. In critical applications such as fire protection or industrial processing, their robust design allows for smooth flow control, reducing energy losses and maintenance downtime, which in turn optimizes overall operational effectiveness.

Beyond basic functionality, these valves integrate smart features like real-time monitoring and automated adjustments, enabling proactive maintenance and faster response times. This adaptability not only boosts efficiency but also enhances safety by preventing potential hazards before they escalate, making them a preferred choice for high-stakes scenarios where precision and reliability are paramount.

In comparison to standard valves, UL FM gate valves offer superior sealing technology and durability, proven through rigorous testing under extreme conditions. This translates to longer service life and consistent performance, reducing the need for frequent replacements and lowering long-term costs. Their role in streamlining processes and ensuring uninterrupted operations underscores why they are vital for maximizing efficiency in critical infrastructure and industrial systems.

When selecting UL FM gate valves, start by examining their pressure ratings to ensure they can handle the specific demands of your system. Look for valves that undergo rigorous testing for both upstream and downstream conditions, as this directly impacts their reliability in fire protection applications. Additionally, consider the valve's material composition—stainless steel or bronze often offer better durability and corrosion resistance compared to standard options.

Another critical aspect is the valve's design for easy maintenance and accessibility. Features like a non-rising stem or a visible position indicator can simplify inspections and reduce downtime in emergency situations. Don't overlook the importance of compatibility with your existing piping layout; some models offer more flexible installation options, which can save time and costs during setup.

Finally, verify the manufacturer's reputation and certification compliance. A valve that meets UL and FM standards should come with clear documentation and support services. Real-world performance reviews from other users can also provide insights into long-term durability and operational efficiency, helping you choose a valve that stands out for its reliability and ease of use.

When evaluating UL FM gate valves, it's crucial to dig beyond basic specifications to understand real-world performance under fire protection scenarios. These valves must meet rigorous standards set by Underwriters Laboratories and FM Global, but how do they actually hold up in terms of flow dynamics and pressure handling? Recent tests reveal that top-performing models exhibit minimal pressure drop and reliable sealing, even after repeated cycles—key factors in ensuring water supply continuity during emergencies. This makes them indispensable for high-risk environments like industrial plants.

Durability is another cornerstone where these valves shine, often outperforming generic alternatives in longevity and resistance to corrosion. We've seen cases where UL FM-certified valves withstand harsh conditions for decades without significant wear, thanks to robust materials like cast iron or bronze and enhanced design features. This translates into lower maintenance costs and fewer emergency shutdowns, offering a compelling return on investment that goes beyond mere compliance.

In the competitive market, not all valves labeled with UL FM are created equal; differences in manufacturing processes and quality control can lead to varied outcomes. By comparing specific models side-by-side, insights emerge on which valves offer the best balance of performance and durability—helping professionals make informed choices that prioritize safety and reliability over price alone.

When installing UL FM gate valves, start by ensuring the pipe ends are thoroughly cleaned and deburred to prevent debris from compromising the seal. Align the valve precisely with the pipeline to avoid undue stress on the body, which can lead to leaks or operational issues. It's also wise to check the valve's orientation—typically marked with flow direction arrows—to guarantee proper function and compliance with UL FM standards for fire protection systems.

Another key tip is to use appropriate gaskets and torque specifications during installation. Over-tightening bolts can warp the valve components, while under-tightening might cause leaks under pressure. Refer to the manufacturer's guidelines for exact torque values, and consider using a calibrated torque wrench to achieve consistent results. This attention to detail helps maximize the valve's lifespan and ensures it performs reliably in emergency scenarios.

After installation, conduct a thorough inspection and test the valve under system pressure to verify no leaks and smooth operation. Regular maintenance, like lubricating stem threads and checking for corrosion, should be part of the routine to keep the valve optimized over time. By following these steps, you'll enhance both safety and efficiency in your fire protection setup.

In the industrial valve landscape, UL FM gate valve technology is steering toward smarter, more resilient designs that prioritize predictive maintenance and environmental compliance. Manufacturers are increasingly integrating IoT sensors and embedded diagnostics to monitor real-time performance metrics like pressure, temperature, and wear, enabling proactive servicing before failures occur. This shift not only reduces downtime but also aligns with stringent safety standards, particularly in high-risk sectors such as petrochemicals and power generation, where operational integrity is paramount.

Material innovations are another key trend, with a growing emphasis on advanced alloys and composite materials that enhance corrosion resistance and durability under extreme conditions. Research is focusing on nano-coatings and self-lubricating surfaces to minimize friction and extend valve lifespan, addressing common challenges in harsh industrial environments. These advancements support longer service intervals and lower total cost of ownership, making UL FM gate valves a more cost-effective and sustainable choice for modern facilities.

Looking ahead, connectivity and automation will likely define the next wave, with gate valves being seamlessly integrated into broader industrial control systems for automated flow regulation and remote operation. This evolution toward Industry 4.0 standards promises improved efficiency and safety, allowing for rapid response to changing industrial demands while maintaining rigorous UL and FM certifications.

FAQ

UL FM gate valves combine rigorous testing by Underwriters Laboratories (UL) and Factory Mutual (FM), ensuring they meet strict fire safety standards, which helps prevent system failures during emergencies.

These valves are designed for minimal pressure drop and durable, leak-free operation, reducing downtime and maintenance needs, thus streamlining processes.

Materials like stainless steel and bronze are often used because they resist corrosion and high temperatures, ensuring reliability in harsh industrial environments.

They are essential in fire protection systems, chemical plants, and oil refineries where safety and reliability are paramount for controlling hazardous fluid flows.

Consider factors like valve size, pressure rating, material compatibility, and certification requirements by UL and FM to ensure proper fit and safety compliance.

Regular inspections for wear, lubrication of moving parts, and testing for leaks are key; following manufacturer guidelines helps maintain optimal function.

UL and FM certifications focus specifically on fire safety and loss prevention, offering more targeted assurance than general industry standards, which can minimize risks.

Yes, customization options include special coatings, sizes, and actuation methods to handle specific pressures, temperatures, or automation requirements.

Conclusion

When selecting UL FM gate valves, prioritize features like durable materials, corrosion resistance, and tight sealing mechanisms that meet stringent safety standards. These aspects ensure optimal performance in critical industrial settings, enhancing both safety and operational reliability. By comparing various models, users can identify valves that offer the best balance of performance and longevity, supporting efficient system operations.

Proper installation techniques, as noted in best practices, further optimize valve functionality and contribute to long-term efficiency. Looking ahead, emerging trends in UL FM gate valve technology promise innovations that will improve automation and sustainability in industrial applications. This guide equips professionals with essential insights to make informed decisions, ensuring their systems remain safe, efficient, and adaptable to future advancements.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com