Mesh conveyor wire belts can be customized for specific applications

2023-10-31

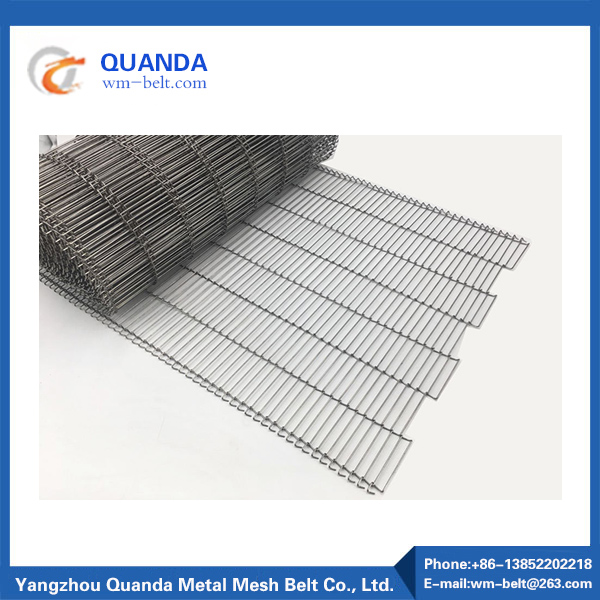

Mesh conveyor wire belts can be customized to meet the specific requirements of different applications. Customization is a key feature of these belts and is one of the reasons they are widely used in various industries. Here are some ways in which mesh conveyor wire belts can be customized for specific applications:

1. Mesh Size and Pattern: The size and pattern of the mesh can be customized to accommodate different product sizes and shapes. Some applications may require a tighter mesh for smaller items, while others may need a more open mesh for better airflow and drainage.

2. Material Selection: The choice of material is crucial and can be customized based on factors such as temperature resistance, corrosion resistance, and product compatibility. Stainless steel, carbon steel, Inconel, and other alloys are available options.

3. Belt Width and Length: The width and length of the belt can be customized to fit the dimensions of the conveyor system and the specific layout of the production line.

4. Edge Reinforcement: To prevent fraying or damage to the edges of the belt, edge reinforcement can be added in the form of crimped edges or welded edges.

5. Endless or Open-Ended Belts: Mesh conveyor wire belts can be customized as endless belts (where the ends are joined) or as open-ended belts, depending on the conveyor system and the ease of installation and replacement.

6. Surface Coatings: Some applications benefit from additional coatings, such as non-stick coatings like PTFE (Teflon), to reduce product adhesion or coatings for increased durability and corrosion resistance.

7. Cleats and Sidewalls: Cleats or sidewalls can be added to the belt to assist in incline or decline conveying or to contain products on the belt during transport.

8. Tracking and Tensioning Mechanisms: Custom tracking and tensioning mechanisms can be incorporated to ensure the belt runs smoothly and remains properly tensioned.

9. Food-Grade and Sanitary Options: In the food industry, belts can be customized to meet strict food safety and hygiene standards, including designs that facilitate easy cleaning and prevent product contamination.

10. Drive Systems: The belt can be customized to work with different drive systems, including sprocket drives, drum drives, and more, depending on the specific conveyor setup.

Customization ensures that the mesh conveyor wire belt is tailored to the unique needs and challenges of a particular application, which can improve efficiency, product quality, and overall system performance. Manufacturers and suppliers often work closely with customers to design and produce belts that meet their precise specifications.