Selecting the Right Grade: Factors Influencing Stainless Steel Grades for Cylinder Liners in Engine Applications

2024-02-20

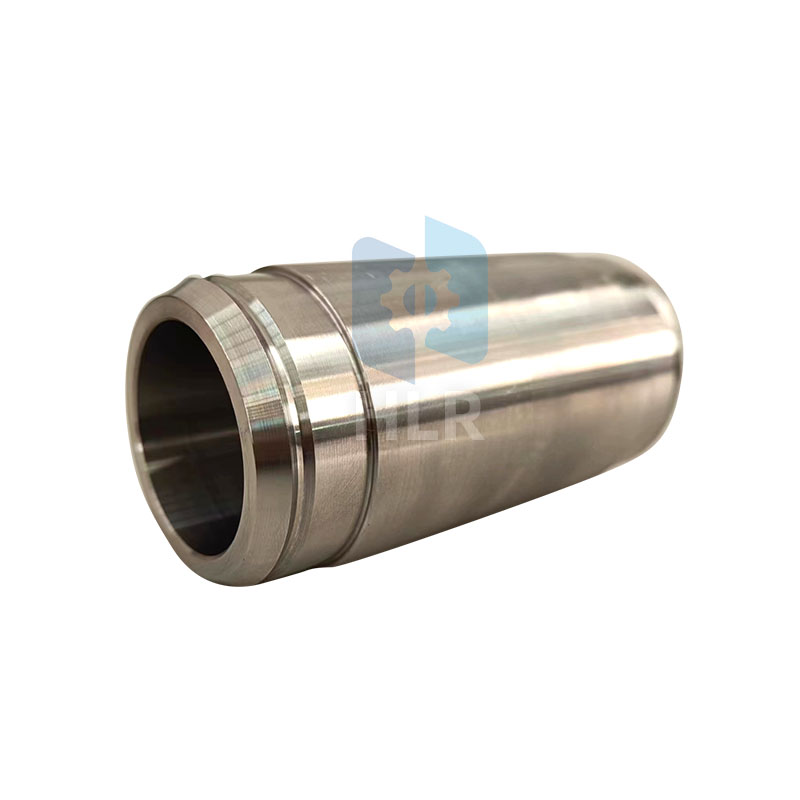

In the realm of engine design, where performance, durability, and reliability are paramount, the selection of stainless steel grades for cylinder liners is a critical decision. Different engine applications require specific properties and characteristics from cylinder liners to ensure optimal performance and longevity. From high-performance sports cars to heavy-duty industrial machinery, various factors influence the choice of stainless steel grades for cylinder liners. Let's explore these factors and understand how they shape the selection process.

Engine Type and Application

The type of engine and its intended application play a fundamental role in determining the appropriate stainless steel grade for cylinder liners. Factors such as operating temperatures, mechanical stresses, and environmental conditions vary significantly across different applications, influencing material selection accordingly.

- High-Performance Engines: Engines in sports cars, racing vehicles, and performance-oriented applications demand stainless steel grades with high strength, corrosion resistance, and heat dissipation capabilities to withstand extreme conditions and deliver maximum power output.

- Industrial Engines: Engines used in heavy-duty industrial applications, such as construction equipment, agricultural machinery, and power generators, require stainless steel grades with superior durability, wear resistance, and thermal stability to withstand prolonged use and harsh operating environments.

Thermal Management Requirements

Efficient heat dissipation is crucial for maintaining optimal engine performance and preventing overheating-related issues. The thermal conductivity and thermal expansion characteristics of stainless steel grades influence their suitability for cylinder liners in different engine applications.

- High Thermal Conductivity: Engines operating at high temperatures or under heavy loads benefit from stainless steel grades with high thermal conductivity, facilitating rapid heat transfer away from the combustion chamber and minimizing thermal stress on cylinder liners.

- Low Thermal Expansion: Stainless steel grades with low coefficients of thermal expansion are preferred for applications where dimensional stability is critical, ensuring minimal distortion and maintaining tight tolerances under fluctuating temperatures.

Corrosion Resistance and Environmental Factors

The corrosive nature of operating environments, exposure to contaminants, and compatibility with fuels and lubricants are essential considerations in selecting stainless steel grades for cylinder liners.

- Corrosion Resistance: Engines operating in marine environments, coastal regions, or areas with high humidity and chemical exposure require stainless steel grades with superior corrosion resistance to prevent rust, pitting, and degradation over time.

- Environmental Regulations: Compliance with environmental regulations, such as emissions standards and pollution control measures, may influence the selection of stainless steel grades with specific alloy compositions or surface treatments to minimize environmental impact and ensure regulatory compliance.

Manufacturing Constraints and Cost Considerations

Practical considerations, such as manufacturing capabilities, cost constraints, and supply chain logistics, also influence the selection of stainless steel grades for cylinder liners.

- Manufacturability: Stainless steel grades that are easily machinable, forgeable, or castable may be preferred for streamlined manufacturing processes and cost-effective production of cylinder liners.

- Cost-Efficiency: Balancing performance requirements with cost considerations is essential in selecting stainless steel grades that offer the best combination of performance and affordability for a given engine application.

Conclusion

The selection of stainless steel grades for cylinder liners in engine applications is a multifaceted decision influenced by a myriad of factors, including engine type, thermal management requirements, environmental factors, and manufacturing constraints. By carefully considering these factors and choosing the most suitable stainless steel grades, engineers can ensure optimal performance, durability, and reliability of cylinder liners across diverse applications, driving innovation and excellence in the field of engine design and manufacturing.