Tailored Solutions: Customizing the Intelligent Factory Supply Automated Edge Banding Cell for Diverse Production Needs

2024-03-15

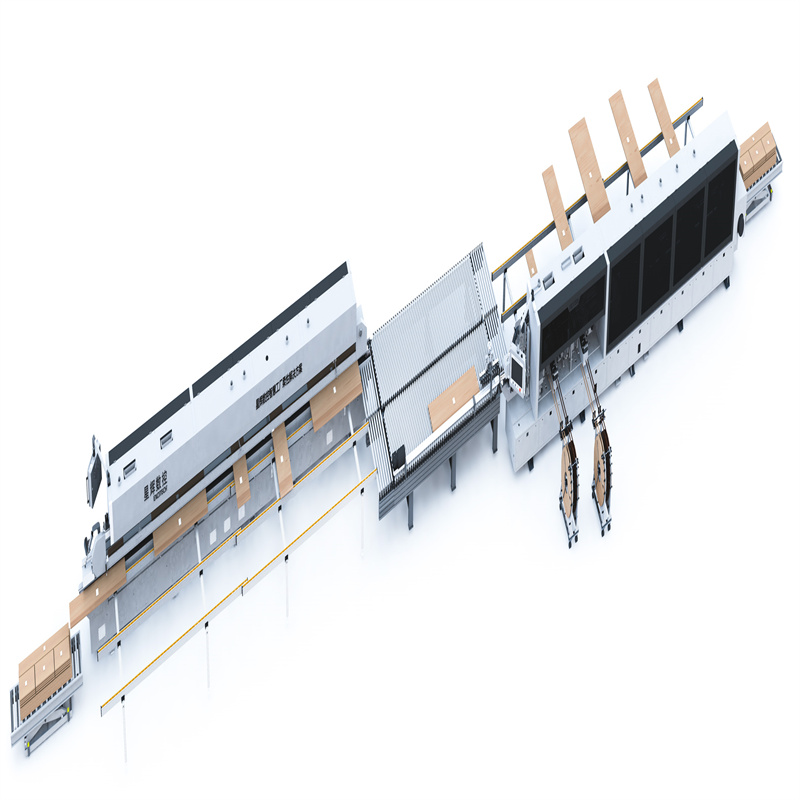

In the realm of manufacturing, flexibility and adaptability are paramount. Each production environment is unique, with its own set of requirements, challenges, and specifications. In response to this diversity, the Intelligent Factory Supply Automated Edge Banding Cell offers a customizable and configurable solution that can be tailored to meet specific production requirements and accommodate a wide range of materials. In this blog, we'll explore how the Intelligent Factory Supply Automated Edge Banding Cell can be customized and configured to address the diverse needs of modern manufacturing.

1. Modular Design:

One of the key features of the Intelligent Factory Supply Automated Edge Banding Cell is its modular design. This design allows for easy integration of additional components, accessories, and functionalities to tailor the system to specific production needs. Whether it's adding a CNC machining center for additional processing capabilities or incorporating specialized sensors for quality control, the modular design of the edge banding cell enables manufacturers to customize the system to meet their exact requirements.

2. Adjustable Settings and Parameters:

The Intelligent Factory Supply Automated Edge Banding Cell offers adjustable settings and parameters that can be fine-tuned to accommodate different types of materials and production specifications. Parameters such as feed speed, pressure, temperature, and adhesive application can be adjusted to optimize edge banding performance based on the properties of the material being processed. This flexibility ensures consistent and reliable results across a variety of material types and thicknesses.

3. Compatibility with Various Edge Banding Materials:

Edge banding cells are designed to work with a wide range of edge banding materials, including PVC, ABS, wood veneer, and more. The Intelligent Factory Supply Automated Edge Banding Cell can be configured to accommodate different types of edge banding materials, with options for various widths, thicknesses, and finishes. Whether it's applying thin PVC edge banding to delicate furniture components or thicker ABS edge banding to heavy-duty cabinetry, the edge banding cell can handle it all.

4. Integration with Other Manufacturing Systems:

The Intelligent Factory Supply Automated Edge Banding Cell is designed to seamlessly integrate with other manufacturing systems and processes, allowing for a holistic approach to production optimization. Whether it's connecting with upstream processes such as panel cutting and sanding or downstream processes such as assembly and packaging, the edge banding cell can be configured to fit seamlessly into existing workflows. This integration enables manufacturers to achieve greater efficiency, consistency, and throughput throughout the production cycle.

5. Customization for Specialized Applications:

In addition to accommodating different types of materials, the Intelligent Factory Supply Automated Edge Banding Cell can be customized for specialized applications and unique production requirements. Whether it's adding specialized tooling for intricate edge profiles, implementing specific quality control measures for high-precision components, or incorporating robotics for automated material handling, the edge banding cell can be tailored to meet the most demanding production challenges.

In conclusion, the Intelligent Factory Supply Automated Edge Banding Cell offers a customizable and configurable solution that can be tailored to meet the diverse needs of modern manufacturing. From modular design and adjustable settings to compatibility with various edge banding materials and integration with other manufacturing systems, the edge banding cell provides manufacturers with the flexibility and adaptability they need to optimize production workflows and achieve their production goals. With its ability to be customized and configured for specific applications, the edge banding cell is truly a versatile solution that empowers manufacturers to succeed in today's competitive market landscape.

Intelligent Factory Supply Automated Edge Banding Cell

Intelligent Factory Supply Automated Edge Banding Cell