The Evolution of Paint-Dipped Grating: Innovations and Applications

2024-07-25

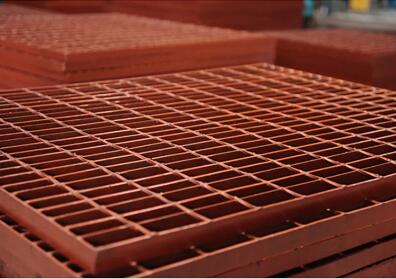

In the dynamic landscape of industrial and architectural design, materials play a pivotal role in shaping the functionality, durability, and aesthetic appeal of structures. Paint-dipped grating, a versatile solution born from advancements in coating technology and material science, continues to evolve as a preferred choice for diverse applications across various industries.

Understanding Paint-Dipped Grating

Paint-dipped grating refers to grating panels that have been coated with a protective layer of paint or powder coating. This additional layer serves multiple purposes, primarily enhancing the grating's resistance to corrosion and wear while offering customization options in terms of color, texture, and surface finish.

Technological Advancements

The evolution of paint-dipped grating has been driven by innovations in coating technologies and manufacturing processes:

- Advanced Surface Preparation: Modern surface preparation techniques ensure thorough cleaning and treatment of grating materials, promoting strong adhesion of the paint coating. This step is crucial for maximizing durability and longevity.

- Precision Coating Application: Automated coating systems allow for precise application of paint or powder coatings, ensuring uniform coverage and consistent thickness across grating panels. This not only enhances aesthetic appeal but also optimizes the protective properties of the coating.

Key Benefits

1. Durability and Corrosion Resistance: The primary advantage of paint-dipped grating lies in its ability to withstand harsh environmental conditions. The paint or powder coating acts as a barrier against moisture, chemicals, and UV radiation, thereby extending the lifespan of the grating and reducing maintenance requirements.

2. Customization Options: Design flexibility is a significant benefit of paint-dipped grating. Architects and designers can choose from a wide range of colors, textures, and finishes to achieve specific design objectives and seamlessly integrate grating into diverse architectural styles and environments.

3. Enhanced Safety: Paint-dipped grating can be engineered with anti-slip properties, enhancing traction on walking surfaces and reducing the risk of slips and falls. This feature is crucial for applications in industrial settings, public spaces, and areas prone to wet or oily conditions.

Applications Across Industries

Paint-dipped grating finds versatile applications across various industries and environments:

- Industrial Facilities: Used extensively in manufacturing plants, refineries, and chemical processing facilities for flooring, platforms, and stair treads where robust and corrosion-resistant materials are required.

- Commercial Buildings: Integrated into shopping malls, airports, and office complexes to provide safe and visually appealing flooring solutions for pedestrian traffic.

- Architectural Design: Utilized in building facades, bridges, and urban infrastructure projects to combine structural support with aesthetic enhancement, contributing to the overall visual harmony of modern urban landscapes.

Future Trends and Innovations

Looking ahead, the future of paint-dipped grating is poised for further innovation and refinement:

- Sustainable Practices: Emphasis on eco-friendly coatings and materials that minimize environmental impact while maintaining high performance.

- Integration of Smart Technologies: Incorporation of sensors and digital monitoring systems to enhance maintenance efficiency and performance monitoring of grating installations.

- Advancements in Coating Durability: Research and development efforts focused on enhancing the durability and longevity of coatings to meet evolving industry standards and requirements.

Conclusion

Paint-dipped grating exemplifies the intersection of functionality, durability, and design versatility in contemporary construction and architectural practices. As industries continue to prioritize efficiency, safety, and sustainability, this innovative solution remains a cornerstone in achieving resilient and aesthetically pleasing built environments. With ongoing advancements in technology and materials, paint-dipped grating is set to play an increasingly pivotal role in shaping the landscapes of tomorrow, offering architects, engineers, and designers a robust canvas for creative expression and practical innovation.